Due to the hot climate in the Middle East, the use of cooling towers is necessary in many factories, power plants, refineries, and petrochemicals.

Function of the cooling tower in these cases is to transfer the heat produced by the production line to the outside environment.

Due to the high air temperature and the number of wet-bulb temperature, in countries such as Iraq, Syria, Afghanistan, Kuwait, Oman, the United Arab Emirates, Qatar, and Bahrain, it will not be possible to design a cooling tower with only refrigeration capacity.

In such cases, an experienced consultant must prepare the technical specifications and cooling tower purchase request based on the circulating water flow rate, inlet temperature, and outlet temperature.

Also, the design consultant should be able to classify the reliable cooling tower manufacturers based on price and quality.

Having a long experience in the industrial cooling tower design and production in the Middle-East, and using European standard software, we can design and advise you in the process of purchasing cooling towers.

- Design of concrete cooling tower (calculation of dimensions and capacity)

- Calculate and estimate the characteristics of the cooling tower of the fiberglass (composite) structure.

- Optimizing and increasing the capacity (refrigerating tons) of the industrial cooling tower

- Choosing the type of filling and amount (height) in packing replacement projects

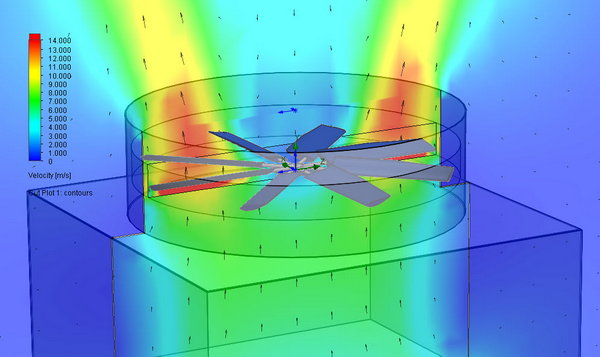

Air flow simulation inside the cooling tower helps designers to examine how air moves from the louver inlet to the fan stack outlet. One of the important applications of cooling tower simulation is to identify eddy currents that can lead to efficiency loss.

Contact us for more information(Telegram, WhatsApp, IMO)

+989124780268