Chemically, the flame is the base division of the fire, which has a lot of heat and chemical reactions take place in it. The flame conditions, its size, and the geometric form that comes out of an industrial burner are critical.

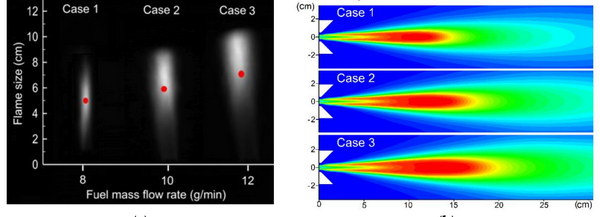

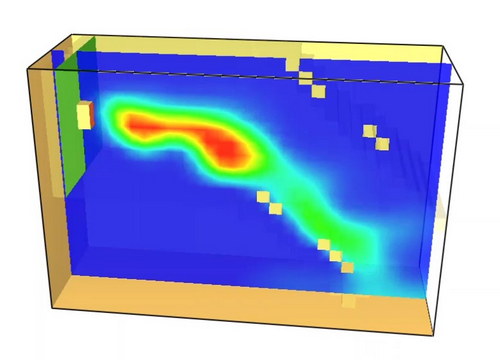

For example, in an industrial gas heater unit, the usually large flame must be created. If we consider the air inlets, we realize that this flame must burn in a way that does not collide with the boundary. That is where simulation and modeling help us predict flame behavior. For another example, consider that you want to implement a design for the geometric form and walls of a furnace or boiler combustion chamber. In this case, the design could be optimized, by modeling the flame geometry.

Applications of flame simulation

Applications of flame simulation

- Checking the geometry of the design and making sure that the flame does not collide directly with the body of the chamber

- Assessing the condition of fresh air intakes

- Estimation of the temperature situation in different places

- Simulation of the combustion chamber of an industrial boiler

- Simulating and optimizing the furnace flame simulationFlame modeling

Effect of time in predicting flame behavior

Effect of time in predicting flame behavior

Considering the time factor, there are two types of simulation in fluid mechanics. The first mode, which is known as steady-state simulation, is executed in conditions where we want to see how the system works in normal mode. For example, CFD simulations of ventilation are usually steady state. This type of simulation can be done based on the system reaching the equilibrium state.

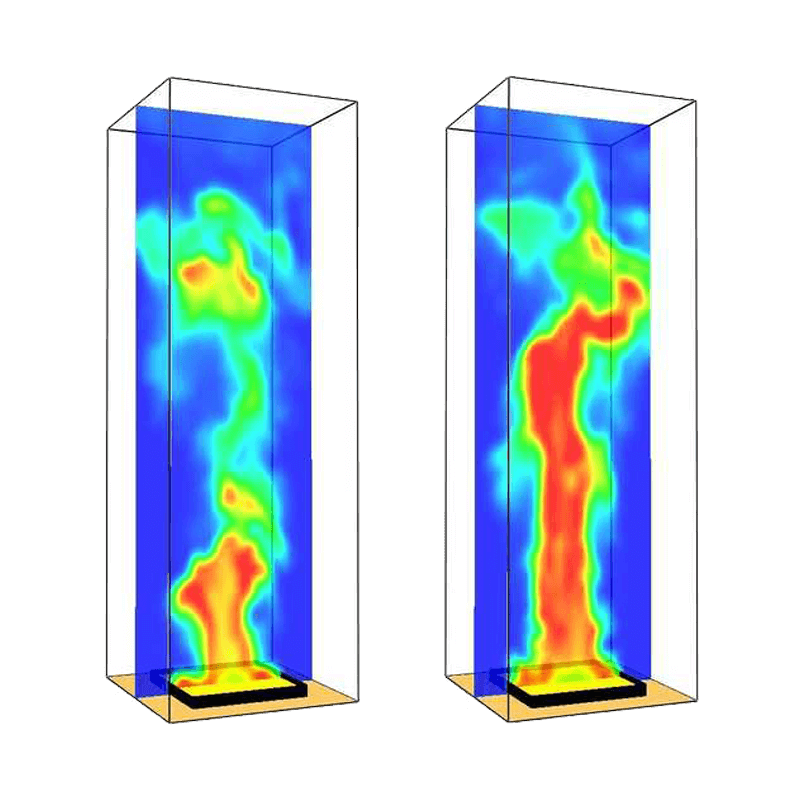

Another type of simulation is called time-transient simulation. In the transient state analysis, it is assumed that the volume of the criterion has not reached equilibrium, and for this reason, the output information will change according to time. Modeling the behavior of fire and smoke is an example of the transient state. The simulation of the flame behavior can be performed in both stable and transient states. The choice between these two methods depends on the employer's expectations. For example, if we want to check the flame shape in an industrial burner, steady-state simulation is acceptable. But if we want to know about the geometrical form and temperature conditions of a large boiler (from the start of the operation), time-transient simulation is the correct choice. In the image below, you can see the results of flame shape analysis in a transient simulation. Flame shape modeling

We are ready to simulate industrial burners and flames based on the client's needs in ARACo.

Contact us for more information.

+989124780268

+982166561974

+9821661297745

ARACo Simulation Services